Pacific Group Developments wants to help educate our clients about the process, parts, materials, installation and assembly of septic treatment plants. This page is designed to help you understand what you need to know about septic treatment plants.

About Septic Treatment Plants

Septic treatment plants are a relatively new development in septic waste management. Most units available today have been on the market for less than 10 years. Septic treatment plants have many benefits over the old conventional systems of an ordinary septic tank alone. Septic treatment plants treat the effluent thoroughly, reducing the particulate entering the field. This improved quality adds to the life expectancy of your field and with a pressurize distribution system (which almost all use) you get 100% efficiency in drain field usage.

How a Septic Treatment Plant Works

All septic treatment plants use the aerobic (with oxygen) digestion process to treat sewage. In this process, oxygen-using bacteria attack and break down the organic portions of the sewage into simpler inorganic compounds. Aerobic treatment is preferred because it’s rapid and relatively odor free. It also provides greater solids reduction.

Septic tank systems rely on the anaerobic (without oxygen) breakdown process, which is much slower and less efficient. It also produces the characteristic septic odor.

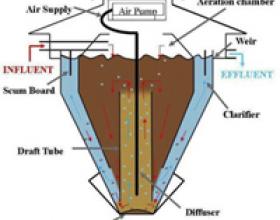

Septic treatment plants maintain aerobic conditions by introducing air into the tank. This can be done in two different ways. Some manufacturers use an external air compressor to bubble air through the sewage. Others draw air into the sewage by using either a pump or a stirring device that functions much the same as a food mixer or blender, thereby creating aeration through movement.

3 Stages of a Septic Treatment Plant

Treatment within the septic treatment plant is accomplished in three stages.

Stage 1:In the first stage, raw sewage enters the system and large particles are settled out or broken up mechanically to increase their surface area and make them more accessible to the aerobic bacteria.

Some systems make use of a separate anaerobic bacteria treatment chamber where anaerobic bacteria break down the larger particles. Anaerobic treatment chambers require more frequent pumping of sludge.

Stage 2: The second phase of the treatment consists of mechanical aeration. Oxygen-containing air is mixed and blended with mixtures of solids and liquid. During this period, aerobic bacteria reduce the sewage into simple compounds.

Stage 3:The final step is the settling or clarification chamber. Treated sewage from the aeration process is emptied into this chamber where the heavier solids in the sewage settle. These solids are returned to the aeration chamber for further processing. The clarified liquid from this chamber either flows or is pumped out of the treatment plant.

It’s good to mention that depending on the situation a septic tank may be used to make up the first chamber of a septic treatment plant and that a pump chamber may be added externally if needed. There are many variations of the septic treatment plants and many different manufacturers of components and full septic treatment plants that it’s easy to make a choice on needs and value.

Septic treatment plants rely on mechanical parts, air pumps and usually an effluent pump. If one of these fails and goes unnoticed it could be very costly to repair the damage to your septic disposal field. Due to the potential costly damages it is standard to have an audible and visual alarm to alert the homeowner to the problem. The pumps, motors and alarm all need electricity and provisions must be made for electrical service to the septic treatment plant location.